Automated Guided Vehicles (AGVs) are robotic vehicles that are designed to perform tasks in an industrial or commercial setting without the need for human intervention or guidance. AGVs are typically equipped with sensors, navigation systems, and control mechanisms that allow them to navigate through a predetermined path or interact with their environment autonomously.

AGVs are an integral part of smart factory and warehouse systems, where they take charge of repetitive tasks, material handling, and logistics with astonishing precision and speed. Equipped with laser scanners, cameras, and other sensors, AGVs navigate through their surroundings, detecting obstacles and swiftly adapting their routes to ensure optimal performance and safety.

Download BrochureAutonomous Mobile Robots (AMRs) are robotic devices capable of operating and navigating in dynamic environments without constant human control or guidance. They are equipped with sensors, onboard computing power, and sophisticated algorithms that enable them to perceive their surroundings, plan their movements, and execute tasks autonomously. AMRs are designed to perform a wide range of applications in industries such as manufacturing, logistics, healthcare, agriculture, and more.

AMRs offer increased flexibility, efficiency, and scalability in various industries by automating repetitive or physically demanding tasks. They can adapt to changing requirements, optimize workflows, and enhance overall operational performance. With advancements in artificial intelligence and robotics, AMRs are becoming increasingly capable and are transforming industries by enabling greater automation and improving productivity.

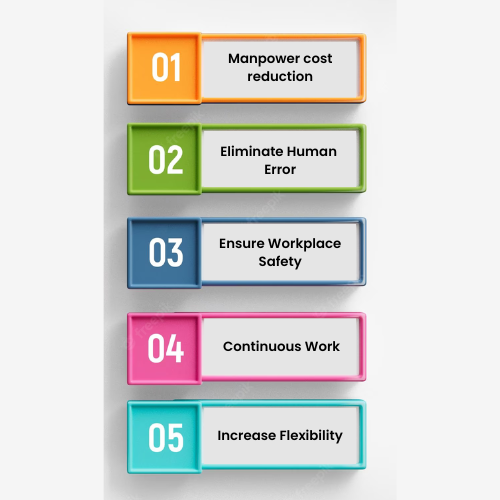

Cost Savings

While the initial investment in AMRs may be higher, they can

result in long-term cost savings. AMRs eliminate or reduce the need for manual labor,

minimizing labor costs and the associated expenses such as training, benefits, and overtime

pay.

Increased Efficiency

AMRs use various navigation technologies such as

lidar, cameras, or simultaneous

localization and mapping (SLAM) to perceive their surroundings and navigate in complex

environments.

Improved Safety

AMRs help improve workplace safety by taking over hazardous

or physically demanding tasks. They can handle tasks in dangerous environments, work in

proximity to heavy machinery, or handle hazardous materials, reducing the risk of accidents

and injuries to human workers.

Flexibility and Scalability

AMRs are designed to be flexible and easily

adaptable to changing operational requirements. They can be reprogrammed or reconfigured to

perform different tasks or adjust to evolving production needs, allowing businesses to scale

their operations effectively.

24/7 Operations

AMRs can operate continuously without the need for breaks

or rest, enabling 24/7 operations. This allows businesses to increase productivity and meet

customer demands more efficiently, especially in industries with round-the-clock

requirements such as e-commerce or logistics.

Increased Accuracy and Quality

AMRs consistently perform tasks with

precision and accuracy, minimizing errors and improving the quality of work. This is

particularly beneficial in areas such as pick and place operations, where accuracy and

attention to detail are crucial.

An autonomous mobile robot is a machine capable of performing tasks or navigating its environment without direct human intervention. It uses sensors, algorithms, and artificial intelligence to perceive and understand its surroundings, make decisions, and move autonomously.

The future of autonomous mobile robots is promising. Advancements in artificial intelligence, sensor technology, and robotics will continue to improve their capabilities. We can expect to see increased deployment of robots in various industries, more sophisticated collaboration between humans and robots, and further integration of these robots into our daily lives to enhance productivity and efficiency.

Safety is a crucial aspect of autonomous mobile robot design. Manufacturers and developers implement various safety features and standards to ensure the safe operation of these robots around humans. These can include collision avoidance systems, emergency stop buttons, fail-safe mechanisms, and adherence to safety regulations specific to the application and industry.

Autonomous mobile robots are used in various industries and applications, such as logistics and warehousing, manufacturing, healthcare, agriculture, security, and more. They can be used for tasks like material handling, inventory management, picking and packing, surveillance, inspection, and even assisting in medical procedures.